August 27, 2015 by Steve Murray

Multipurpose Micro Machines – Robotic Fish from 3D Printing

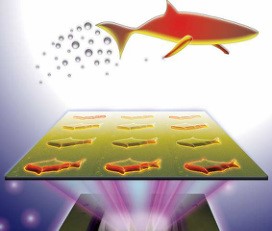

3D-printed microfish containing functional nanoparticles are capable of sensing and removing toxins (J. Warner, UC San Diego Jacobs School of Engineering)

Nanoengineers have used an innovative 3D printing technology to manufacture quantities of multipurpose, self-propelled, and controllable microrobotic “fish,” each smaller than the width of a human hair.

Some basic chemical tools, embedded in the microfish during the fabrication process, enable them to perform useful work.

The project team hopes that the work will inspire a new generation of smart microrobots with capabilities that can be applied to sensing, directed drug delivery, and environmental detoxification.

Precise batch printing

The research was led by Professors Shaochen Chen and Joseph Wang of the NanoEngineering Department at the University of California, San Diego. The team combined Chen’s 3D printing technology with Wang’s expertise in microrobotics to quickly print hundreds of microrobots with some unique properties.

The technology, Microscale Continuous Optical Printing (μCOP), was developed in Chen’s lab. The heart of the printing system is a digital micromirror array device (DMD), a chip with approximately two million individually-controllable micromirrors. Each mirror projects ultraviolet (UV) light onto a photosensitive material that hardens when exposed to the light. The robots are built up one layer at a time to achieve a desired shape. At each stage, a set of functional nanoparticles can be embedded into parts of the shape to yield a sophisticated end product.

The rapid, high-resolution 3D printing system is faster and more flexible than earlier micro-manufacturing techniques and can print hundreds of small robots in a single array. Each microfish in the current study was only 120 microns (.005 inches) long and 30 microns (.001 inches) thick. A human hair, in comparison, is about 75 microns (.003 inches) thick.

Alternative construction methods for microrobots involve combinations of simple designs such as spheres or cylinders made of identical, inorganic materials.

The digital control technology of the μCOP system allowed the research team to rapidly experiment with a wide range of shapes.

“With our 3D printing technology, we are not limited to just fish shapes. We can rapidly build microrobots inspired by other biological organisms such as birds,” said Wei Zhu, a Ph.D. student in Chen’s research group and co-author of the study report.

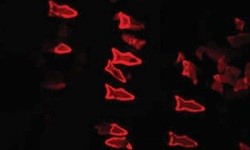

Fluorescent image demonstrating the detoxification capability of the microfish (W. Zhu and J. Li, UC San Diego Jacobs School of Engineering)

Flexible fish

The researchers used μCOP to fabricate a set of controllable, swimming microfish in a proof-of-concept study. Platinum nanoparticles, embedded in the fish tails during the printing process, reacted with their hydrogen peroxide swimming medium to propel the robots. Iron oxide nanoparticles embedded in the fish heads allowed the researchers to steer them with magnets. These simple capabilities prepared the fish for some useful jobs.

Adding polydiacetylene (PDA) nanoparticles to the microfish bodies turned the microfish into a collective cleanup crew. PDA nanoparticles capture harmful toxins like those found in bee venom. The swimming microfish promptly neutralized the toxins in the solution they were placed in. Because PDA nanoparticles emit a red light when they bind with toxin molecules, the researchers could also monitor the progress of the detoxification process by the intensity of the glow.

Functionalizing the microfish with nanoparticles (W. Zhu and J. Li, UC San Diego Jacobs School of Engineering)

More shapes, more functions

The nanoengineering team would like to explore the use of 3D printed microrobots as a medical tool. Microfish are small enough to be injected into the body. Embedding them with medicines could provide an alternative method for drug delivery.

“This method has made it easier for us to test different designs for these microrobots and to test different nanoparticles to insert new functional elements into these tiny structures,” said Jinxing Li, a PhD student in Wang’s research group and the other co-author of the study report. “It’s my personal hope to further this research to eventually develop surgical microrobots that operate safer and with more precision.”

Nanotechnologies are being actively developed for a wide range of applications, including health, energy, and environmental remediation. The ability to control and transport nanomaterials with large numbers of rapidly-fabricated, precision microrobots may be the essential enabling step toward major progress in this field.

Primary Source

These microscopic fish are 3D-printed to do more than swim